X-RAY RUNS: Apply for Beamtime

2017 Nov 1 - Dec 21

2018 Feb 7 - Apr 3

2018 Proposal/BTR deadline: 12/1/17

2018 Apr 11 - Jun 4

2018 Proposal/BTR deadline: 2/1/18

K.D. Finkelstein (CHESS) and Paul Cottle (Cornell

University)

CHESS, always at the cutting edge of innovation in x-ray optics, has

begun exploiting resources at the Cornell Nanofabrication Laboratory to

develop a new generation of focusing elements. The work adapts

micro-electro-mechanical system (MEMS) fabrication techniques to reduce

the size of structures in silicon used to collect, diffract, and focus

x-ray beams.

As a first application, we are improving our sagittal focusing

monochromator crystals that gather and focus a large horizontal swath of

synchrotron radiation. These crystals are thin (~1mm) triangles with

deep rectangular groves (gums) cut perpendicular to the altitude. The

"teeth" adjacent to the gums counteract the anticlastic bending that

occurs due to the sagittal bend. This type of x-ray optic produces a

focal spot limited in size by the synchrotron source (particle beam size

in the storage ring), the sagittal tooth size (individual diffracting

regions on the crystal), and the focal distances. For the typical 1 to 3

focal ratio, a small focal spot requires the tooth width be ¼ of the

source size. If one also wants to maximize flux in the focal spot, it is

important to maximize the number of teeth cut into these crystals.

We are currently making full sized crystals from 4 inch diameter wafers,

with equal gum and tooth widths of 250 microns, containing 125 teeth

approximately 1 mm. tall. These features are smaller than can typically

be achieved with traditional diamond-blade cutting, and with much less

breakage of delicate crystals during processing. This technique produces

virtually no surface damage and so there is no need to use strong acids

to etch away damage.

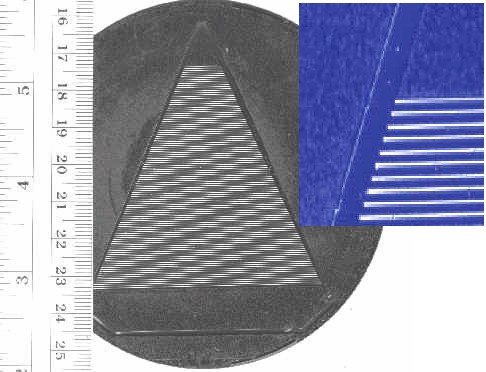

A triangular crystal is etched out of a 4 inch

silicon wafer. The inset shows the 1mm deep, 250 micron wide grooves

that give the crystal enough flexibility to bend without breaking or

becoming distorted. The light horizontal lines are groove edges.