X-RAY RUNS: Apply for Beamtime

2017 Nov 1 - Dec 21

2018 Feb 7 - Apr 3

2018 Proposal/BTR deadline: 12/1/17

2018 Apr 11 - Jun 4

2018 Proposal/BTR deadline: 2/1/18

Discovering new materials often involves searching through hundreds, thousands, or millions of compounds to find exciting new possibilities. Complicating this search further, many new materials need to be heated or cooled in order to transform them into useful products. A group of scientists from Harvard and Cornell have developed a new technique that uses x-rays to explore systematically and quickly an array of new materials while also heating and cooling them at extremely fast rates.

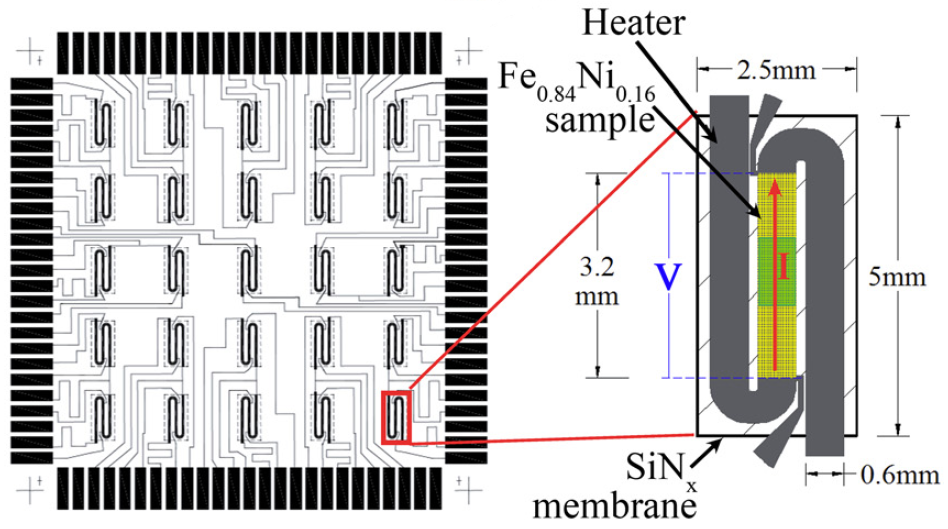

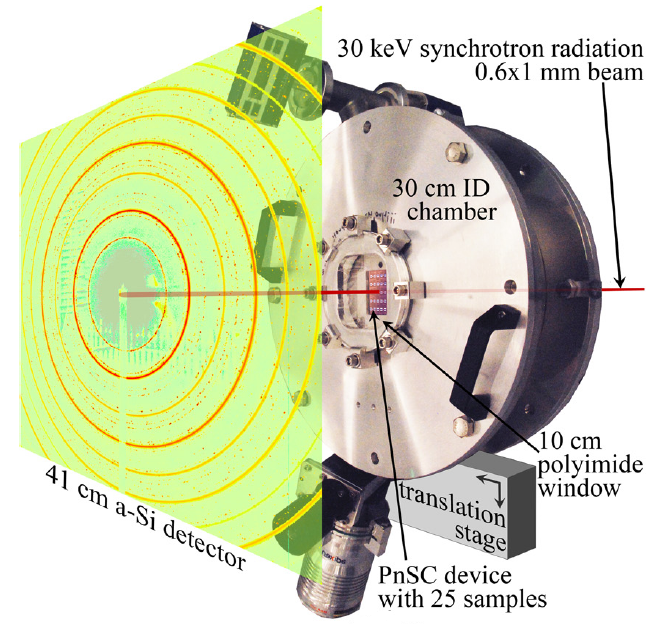

In a paper released recently in Applied Physics Letters [1], lead author John Gregoire describes how thermal and structural details of the transformation behavior of an important iron-nickel alloy can be captured during rapid heating and cooling. The combination of parallel nano-scanning calorimetry (PnSC), which heats and cools a small specimen area rapidly (see figure 1), and x-ray diffraction (XRD) measurements (figure 2) opens up the possibility of studying materials in states far from equilibrium while capturing information both about thermal properties (from PnSC) and structure (from XRD) of the investigated systems. PnSC analyzes thermal properties by quickly sweeping temperature at rates up to 100,000 C degrees per second, as compared to 1 C/s in standard scanning calorimetry measurements. At the same time, in-situ XRD measurements provide additional information required for a more complete understanding of the material reaction.

Figure 1 The metallization of the PnSC device is shown along with the detailed view of a single serpentine sensor that provides uniform sample heating over a broad range of scanning rates. The footprint of the x-ray beam is highlighted in green at center.

By combining two measurement techniques into one instrument, the scientists demonstrated that detailed information could be captured on the transformation behavior of very thin iron-nickel films (picture a piece of steel only a thousandth of an inch thick!) at ultra-fast heating and cooling rates. The unprecedented scanning rates make it possible for a broad range of new materials explorations, from reaction kinetics to high-throughput mapping of phase transformations. High-throughput mapping allows scientists to measure a large number of samples in an automated way; for example, by simply moving the specimen holder, an x-ray beam can illuminates one of twenty-five differently prepared specimens (see figure 1). Development of this technique has been a collaboration between CHESS scientists and both academic and industrial researchers. The Vlassak group went to great lengths to develop an AC nanocalorimetry system and associated micromachined device array in order to support temperature ramps at rates in the 100s K/s, in order to be compatible with time-resolved in-situ x-ray measurements. The flexibility at the CHESS A2 experimental station, overseen by beamline scientist and collaborator Darren Dale, makes possible working with users for technique development that leads to such innovative experiments.

Looking forward, the researchers anticipate this technique could be used to study reactions of solid materials surrounded by gaseous atmospheres. Such studies would be powerful help towards developing high-temperature oxidation resistant materials - that is, materials that don't rust. Other applications might include materials that efficiently utilize water as a thermochemical fuel, which could lead to hydrogen fuel cells to power small to large scale machinery like cell phones to automobiles.

Figure 2 Schematic of the combined nanocalorimetry and synchrotron XRD experiment showing the path of the 30 keV synchrotron beam through the vacuum chamber and nanocalorimeter device. The device can be seen through the polymide window and the detector region is represented by a measured diffraction image.

[1] John M. Gregoire, Kechao Xiao, Patrick J. McCluskey, Darren Dale, Gayatri Cuddalorepatta, and Joost J. Vlassak. "In-situ X-ray diffraction combined with scanning AC nanocalorimetry applied to a Fe0.84Ni0.16 thin-film sample," Applied Physics Letters, vol. 102, 201902-4, 2013.

Submitted by: Margaret K.A. Koker, CHESS, Cornell University

8/26/2013