X-RAY RUNS: Apply for Beamtime

2017 Nov 1 - Dec 21

2018 Feb 7 - Apr 3

2018 Proposal/BTR deadline: 12/1/17

2018 Apr 11 - Jun 4

2018 Proposal/BTR deadline: 2/1/18

When building solar cells made from inorganic bulk heterojunctions (BHJ), donor and acceptor semiconducting materials are deposited from solution and phase separate. This phase separation, and the internal structure of the films, is critical to creating the high interfacial area between domains with distances suitable for charge extraction. Seeking to make the fabrication and performance of solar devices more standard and more predictable, small molecule additives have emerged as viable alternatives to the more widely studied conjugated polymer counterparts primarily since they lack batch-to-batch variability and can be simpler to purify.

However, the lower viscosity of small molecules in solution can make film formation from solution challenging in terms of surface wetting and for achieving significant film thicknesses. And while it is known empirically that nanostructures leading to optimum solar cell performance are often achieved through thermal annealing and/or high-boiling point solvent additives, little is known about the underlying physical structures and why neither treatment addresses the film formation difficulties of small molecule solutions.

In this investigation, a group of thin-film growth experts from the University of California at Santa Barbara and the King Abdullah University of Science and Technology joined forces with CHESS scientist Detlef Smilgies to combine a set of structural characterization tools to probe how the complex internal morphology of the polystyrene (PS)-containing BHJ blends evolve during cure. They collected data in such a way to follow the evolution towards a final organization found in devices and capture the degree to which PS and diiodooctane (DIO) work together to deliver films with optimal performance. Their goal was to draw generalities and mechanistic understandings that could translate to other active layer blends.

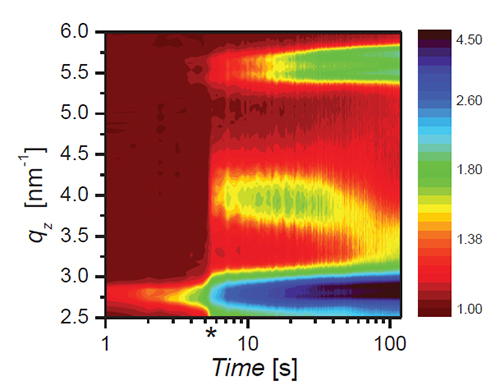

The key to the work was recording grazing incidence small-angle x-ray scattering patterns (GIWAXS) during film deposition and curing. They found that crystalline peaks appear together with the metastable peak, and these conditions may allow the crystallites to serve as nucleation sites during film evolution [1]. Absorption spectroscopy added to the information from GIWAXS experiments, helping to probe order within different length scales and intermolecular organization. Despite the ability of PS to help organize the BHJ components, relative to pure solvent, during the thinning transition, the final arrangement is not the optimal situation as far as power conversion efficiency is concerned. This is where DIO comes into play: due to its low vapor pressure, the time scale for film evolution was extended considerably beyond that of PS alone. Thus the enhancements from both polymer and solvent additives are complementary and synergistic, taking place at different stages during deposition and promoting different ordered phase growth behavior. Although these results are for particular chemical systems, the researchers point out that these insights should apply to other high performance small molecule systems used in BHJ solar cells.

2D color maps of in-situ GIWAXS intensity at qz-values for p-DTS(FBTTh2)2/PC71BM blends over time. The thinning transition is noted by *. These are constructed from GIWAXS x-ray intensity spectra recorded over time.

Reference:

[1] Caitlin McDowell, Maged Abdelsamie, Kui Zhao, Detlef-M. Smilgies, Guillermo C. Bazan, and Aram Amassian: "Synergistic Impact of Solvent and Polymer Additives on the Film Formation of Small Molecule Blend Films for Bulk Heterojunction Solar Cells", Adv. Energy Mater. 2015, online.

Submitted by:

Ernest Fontes, CHESS, Cornell University

08/16/2015