X-RAY RUNS: Apply for Beamtime

2017 Nov 1 - Dec 21

2018 Feb 7 - Apr 3

2018 Proposal/BTR deadline: 12/1/17

2018 Apr 11 - Jun 4

2018 Proposal/BTR deadline: 2/1/18

CHESS-U work on the CESR side is well into the pre-production phase. Most long lead items are on order and production work at Wilson lab is underway for several systems.

- As a reminder, the changes to the storage ring will:

- Provide for single particle beam operation

- Increase storage ring energy from 5.3 → 6.0 GeV

- Increase storage ring current from 100 → 200 mA

- Decrease storage ring emittance to ~< 30 nm

- Increase number of undulator sources from 2 to 10

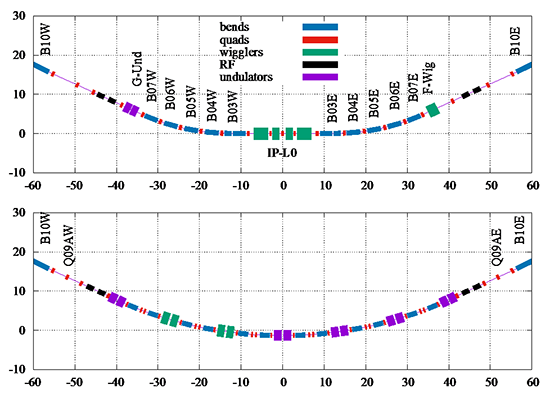

Enabling single beam operation without reduction in numbers of beams and reducing the storage ring beam emittance require major changes to the layout of magnets in the storage ring. 83 meters (11%) of the storage ring must be completely removed to provide space for six double-bend achromat cells to reduce beam emittance and provide suitable beam characteristics at the undulator source points (Fig. 1 below).

Figure 1: Present CESR layout (upper) vs. CHESS-U CESR layout (lower).

Figure 1: Present CESR layout (upper) vs. CHESS-U CESR layout (lower).

While this reconfiguration requires changing many components, the largest, heaviest and most visible components are the magnets. Because of the long lead time for magnet production, priority went to this system to develop, test, and acquire the special combined function (DQ) dipoles and the quadrupoles. All together 12 dipoles, 24 quadrupoles and 48 trim magnets are required for the storage ring upgrade.

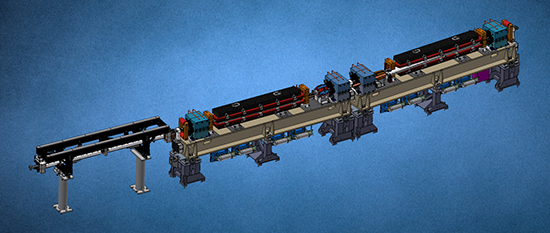

After considering the options for acquisition of these magnets, we chose to design and assemble in house, having coils and iron cores manufactured by local businesses. To facilitate installation and alignment, all magnets will be tested, assembled, and aligned on girders before the installation shutdown begins. Services such as local current regulators, instrumentation wiring and electronics will be preassembled and tested along with local wiring and plumbing. A DBA cell along with adjacent undulator ID straight is shown in Fig. 2.

Figure 2: Undulator magnets and DBA cell.

Figure 2: Undulator magnets and DBA cell.

While the quadrupoles and trim magnets follow conventional designs, the DQ dipoles must combine both Dipole bending and Quadrupole focusing functions. While becoming more common in 4th generation light sources, 50 years have elapsed since combined function magnets were designed and built for the synchrotron at Wilson Lab. For that reason, and to work out details of magnetic measurements, assembly, routing of utilities, etc., a full girder (1/2 the cell above) has been built and will have magnets mounted and wired in the next month.

Physicist Sasha Temnykh and mechanical tech Erik Banta by CHESS-U quadrupole.

Physicist Sasha Temnykh and mechanical tech Erik Banta by CHESS-U quadrupole.

Sasha Temnykh with “DQ” combined-function dipole magnet on girder in measurement lab.

Sasha Temnykh with “DQ” combined-function dipole magnet on girder in measurement lab.

The process of assembling, measuring, aligning and installing all instrumentation, wiring, and plumbing in each of 12 girders is estimated to require 6 weeks each. In order to have all magnets ready to install in summer 2018 the assembly and testing process will be pipelined with activity in 4 separate work areas. Once the magnet coils and iron cores have been received from the vendors they will be checked for compliance to specifications and assembled in area “A”. Local wiring and plumbing will be installed, followed by electrical and water flow tests. After the quadrupoles have been field mapped and trim magnets checked, all magnets will be moved to area “B”, mounted on the girder and roughly aligned by optical survey. The girder with all magnets and local power and water connections will be floated on air pads to the field mapping and alignment area (“C”). Here the DQ magnet will be field mapped and magnetic centers of the quadrupoles aligned with the vibrating wire technique developed at Wilson Lab1. After another optical alignment check, the quadruples will be split and vacuum chamber installed. After reassembly, a final optical check will be made to confirm there is no change in magnet positions. The girder with all magnets will be moved to area “D” in Wilson Lab where power converters, instrumentation, power and water connections will be made and final electrical and water flow checks will be performed.

This plan will produce one complete girder (12 required) every three weeks once the process is underway. Arrangements with vendors for partial deliveries of complete sets of components will allow starting the assembly several months before the final components arrive.

Presently the Magnet Group is evaluating performance of first magnets received from vendors. Full production will be started once any changes in design are made based on evaluation results.

The Magnet Systems Group is led by physicist Sasha Temnykh with engineering by primary engineer Steve Barrett and Aaron Lyndaker when he could break away from beamline work. Technical support from Erik Banta, John Stilwell and Bill Trask has been key to carrying on this work.

More information and photos may be found in CLASSE News for April 7, 2017.

______________________________________

1A. B. Temnykh, NIM-A, 399, pp 185-194, 1997

Submitted by: Dave Rice, CHESS, Cornell University

05/11/2017