X-RAY RUNS: Apply for Beamtime

2017 Nov 1 - Dec 21

2018 Feb 7 - Apr 3

2018 Proposal/BTR deadline: 12/1/17

2018 Apr 11 - Jun 4

2018 Proposal/BTR deadline: 2/1/18

Using pressure rather than chemicals, a joint research team of Brown and Cornell Universities combined their strengths and reshaped nanoparticles into highly monodispersive Janus nanoparticles and helically decorating nanorods. These nanoparticles can find immediate applications in active and living systems for various purposes, such as self-propelled activity, environmental sensor, drug delivery and so on. Unlike chemistry-based techniques which take hours, this newly launched mechanical fabrication approach takes only several minutes at current stage. This breakthrough result has been reported at the early on-line release on 8 June 2017 at the Journal of the American Chemical Society [1].

In the field of soft and living matters, scientists and engineers have made great efforts to fabricate Janus particles, which basically combine the two types of materials with distinct properties into a single particle. It turns out, one material at one side of a particle has the ability to interact with environments and thus produce power. With such self-generated power, these Janus particles make use of the property of different material coded at another side to functionalize with environments in certain ways for desired applications. Currently, the ability enables fabrication of such Janus particles only at micron scale, but has no progress at nanoscale.

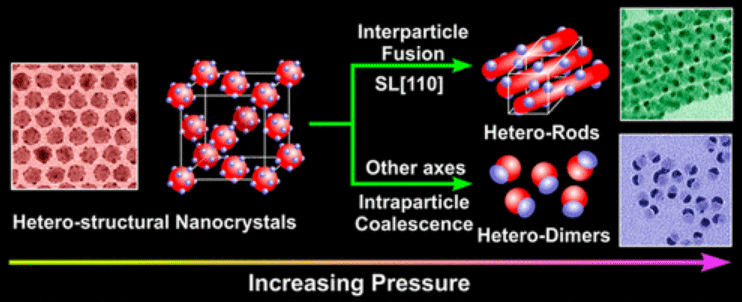

In a close collaboration with CHESS scientist Zhongwu Wang and postdoctoral associate Ruipeng Li, a team led by Prof. Ou Chen and his talented graduate student Mr. Hua Zhu at Brown took advantage of the fast pressure-processing and in-situ monitoring approach and made significant progress in nanomaterials fabrication. They are not only able to fabricate Janus nanoparticles, but can also shape such Janus nanoparticles into helically decorating quantum nanorods by metal nanoparticles. Using synchrotron-based in-situ SAXS and WAXS investigation through the transparent window inside a Diamond anvil Cell (DAC), they also uncovered and reconstructed the stress-induced formation process of such new class of functional nanoparticles. Upon application of a hydrostatic pressure on periodically ordered superlattices assembled by hetero-structure nanoparticles (Figure 1 left), when pressure was reached to a critical point, a differential stress emerged and accordingly drove the satellite metal dots on the surfaces of quantum dot to move and thus fuse into a single dot at one side, which combines another half quantum dot remained at another side to form a Janus nanoparticle (Figure 1, right bottom). This early process did not change the periodic superlattice feature of the starting materials. Upon continuous increase of pressure, the magnitude of differential stress enhanced dramatically and consequently caused the fusion of quantum dot parts of Janus nanoparticles into helically decorating nanorods by metal dots. These nanorods display two dimensionally hexagonal arrays, which can be well redispersed in solutions for additional processing.

Figure 1.

Figure 1.

This pressure-induced fabrication represents a synthetic breakthrough for a fast and efficient creation of new classes of multi-functional nanoparticles. This technique does not involve a clear up of chemical waste, and the operation is also very simple.

Reference:

[1] Zhu H, Nagaoka Y, Hills-Kimball K, Tan R, Yu L, Fang Y, Wang K, Li R, Wang Z, and Chen O, Pressure-Enabled Synthesis of Hetero-Dimers and Hetero-Rods through Intraparticle Coalescence and Interparticle Fusion of Quantum-Dot-Au Satellite Nanocrystals, Journal of the American Chemical Society, 2017, 139 (25), 8408-8411.

Submitted by: Zhongwu Wang, CHESS, Cornell University

09/29/2017