X-RAY RUNS: Apply for Beamtime

2017 Nov 1 - Dec 21

2018 Feb 7 - Apr 3

2018 Proposal/BTR deadline: 12/1/17

2018 Apr 11 - Jun 4

2018 Proposal/BTR deadline: 2/1/18

Contact: E. Fontes (ef11@cornell.edu)

Large x-ray instruments at the Cornell High Energy Synchrotron Source, CHESS, get moved around and reconfigured on a weekly basis. Doing this quickly and reliably is a serious challenge for beamline support staff.

“One of the biggest problems with moving instruments around the lab is having to hook up, reconfigure, verify and troubleshoot computer-controlled stepping motors,” adds head operator Chris Conolly. Missteps lead to lost time for users and potential damage to equipment.

Prior motor systems used complex systems of cabling, patch panels, VME or CAMAC crates and fanout boxes; all create multiple potential points of failure and make troubleshooting difficult if not impossible at times. Placing separate crates or computers at each instrument would be costly and not address having beamline front-end electronics that are simple, compact, and reliable in harsh environments.

Instead, operator Eric Edwards leveraged his interest in CNC machine tools to design a new motor driver system using off-the-shelf, miniaturized industry standard parts. The result is a cost-effective 3.5 inch rack-mount chassis packed with new features; integrating the motion controller and drivers in the same chassis, front-panel access to all features, a simple switch to swap the limit line polarity, straight-through extension cabling, current-setting resistors integrated into the motor connector, and a LAN-based computer interface for remote control.

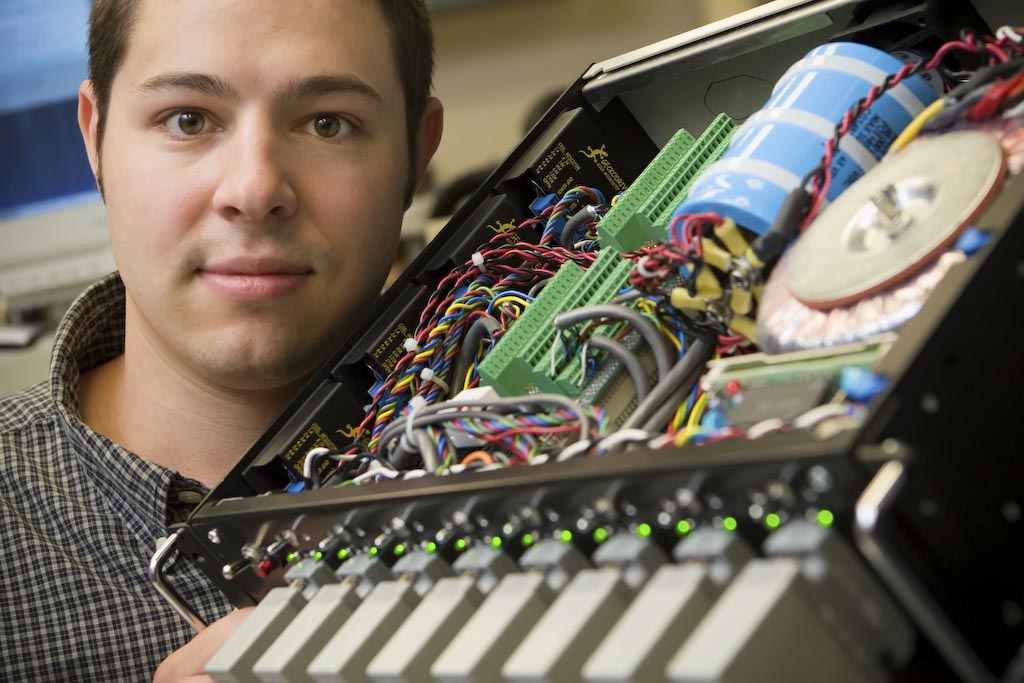

Eric Edwards with first

prototype MDCP stepping motor drive system.

Circuit board layout for the front-panel has

subsequently reduced the wire count by a factor of two

since this photo was taken. [Photo: Frank Dimeo]

The new MDCP box, named for Motor Drive, Control and Power, can be mounted permanently to large instruments such as a diffractometers, optical tables, or x-ray optics boxes. When an instrument moves technicians need only reconnect A/C power and a single RJ45 network line. LAN-based communications allows the MDCP to be only a few feet from motors and permits control and monitoring computers to be virtually anywhere. Motors for beamline front-ends, typically hundreds of feet away from the control room, are now as reliable as local motor installations.