X-RAY RUNS: Apply for Beamtime

2017 Nov 1 - Dec 21

2018 Feb 7 - Apr 3

2018 Proposal/BTR deadline: 12/1/17

2018 Apr 11 - Jun 4

2018 Proposal/BTR deadline: 2/1/18

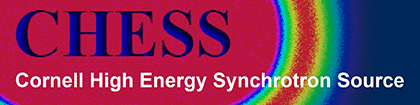

As the last run of 2015 wound down last December 7th, CHESS engineers Alan Pauling and Tom Krawczyk prepared to complete the assembly of two brand-new UHV chambers, along with their valuable cargo: newly-coated, internal-cooled synthetic multilayer monochromators for G-line. The intense push in the subsequent month and a half – involving virtually all of the CHESS technical staff – completed the biggest and most significant upgrade to G-line since 2004. In combination with change from wiggler beam to undulators in late 2014 (see articles on undulator R&D here and here, and commissioning highlights here, and here), and recent improvements to the CESR lattice, these upgrades are delivering best-ever fluxes at G1, G2, and G3 by wide margins and provide G-line with significant new scientific opportunities in future years. The upgrade involved swapping both monochromator pairs for G1 and G2/3, changing the G2/3 monochromatic mirror from a flat mirror to a toroid, and swapping the positions of the G1 and G2/3 monochromatic mirrors to open up an additional upgrade path for G1. Figure 1 shows many of the CHESS technical staff in G-cave days after the upgrade was complete, along with pictures of the three main UHV chambers involved in the work.

Figure 1: (left) CHESS technical staff enjoy a brief moment of relaxation after a two month push to complete the G-line optics upgrade. (upper-right) New UHV chambers for the internal-cooled first multilayer monochromators for G1 and G2/3. (lower-right) UHV chambers housing the G1 and G2/3 monochromatic mirrors, after their upstream/downstream locations were swapped.

- All of the hutches at G-line are now performing better than ever:

- As expected, G3 is consistently delivering approximately 1.4×1014 photons/second into a beam just over 0.6 × 0.6 mm2 at the sample position at 11.3 keV at 120 mA positron current. Thanks to the achromatic-focusing toroidal mirror, installed last September, this focus is maintained over the full G3 energy range from about 8-16 keV.

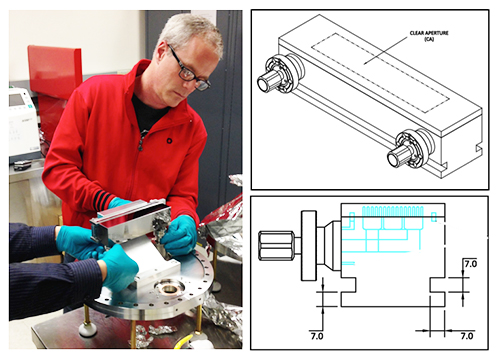

- G2 flux is significantly higher than before – from a historic flux of about 1×1011 to 5×1011 photons/sec in a 0.2 × 2 mm2 beam. In this case, some of the gain arises from improved vertical stability and focusing. But perhaps more important is the fact that the new G2/3 optics were coated with Ru/B4C rather than W/B4C, dropping ΔE/E by a factor of 2-3 but with larger reflectivity above 10.2 keV.

- Finally, G1 now reports approximately 1.4×1012 photons/sec in a highly collimated 0.25 x 0.25 mm2 beam – conditions which previously yielded a maximum of about 7x1011 photons/second.

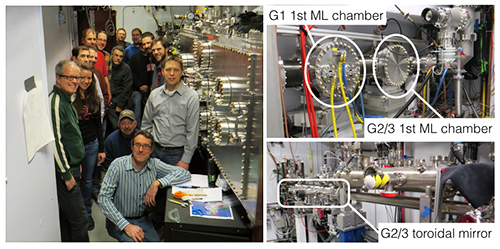

The internal-cooled Si substrates – see Figure 2 – were manufactured by InSync (Albuquerque, NM). Each of these serves as the 1st monochromator for each of the two G-line undulator beams. New, uncooled substrates for the 2nd of each pair of monochromators were fabricated by Gooch & Housego (Moorpark, CA). And all substrate coatings were scrupulously planned and deposited by Rigaku (Auburn Hills, MI). Figure 3 shows the simulated reflectivity and bandwidth curves for both of the new pairs of multilayers now installed at G-line.

Figure 2: (left) Alan Pauling connects one of the conflate flanges on a water line for one of the internal water-cooled multilayer substrates in December 2015. (right) Isometric and front views of the substrates, indicating the arrangement of the internal manifold and fittings.

To accommodate the cooling lines for the new optics, new vacuum chambers were designed in-house (Figure 1 – upper right) and fabricated by Lesker (Jefferson Hills, PA). Unlike the previous multilayer UHV chamber, the new vessels have no internal degrees of freedom. Instead, the vertical position of the monochromator as well as the monochromator angle are adjusted by moving the chambers as a whole, using heavy-duty translation and tilt stages provided by Huber (Lancaster, CA) and Advanced Design Consulting (Lansing, NY) respectively. The long bellows between each cylindrical box are made to accommodate the required ranges of independent motion for each chamber. Traditional monochromator designs call for an additional angular degree of freedom to control the roll or “chi” angle of the optic. The low Bragg angles at which multilayers operate makes deviations of this angle from horizontal less important than with crystal optics. Instead of this additional degree of freedom, a combination of design features in the box and surveying during assembly were used to guarantee that this angle was less than 0.2 degrees from horizontal – sufficiently small to not harm performance.

In addition to installing the new multilayers, a change in the locations of the monochromatic mirrors downstream of the monochromators (Figure 1 – lower right) resulted in a change in the vertical offset between the G1 and G2/3 beams. In order to properly accommodate this change, each of the shielding walls between G-cave and G3 hutch were disassembled to adjust the beam pipes joining each region. Figure 4 shows the G1 walls in this disassembled state. Note the lead bricks remaining in the wall, about half a ton of which were required to be removed and replaced for this operation!

Figure 3: Simulated performance of the new G1 (left) and G2/3 (right) multilayer monochromators now in service at G-line.

Figure 4: Downstram (left) and upstream (middle) of G1 hutch showing the dissambled shielding walls. This was done to adjust the G1 and G2 beampipe positions, to accommodate changes to the lateral and vertical beam positions due to the switch to undulator beams and the swap of the two monochromatic mirrors.

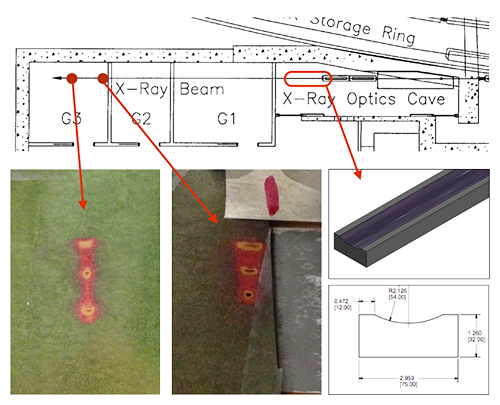

Figure 5 visually highlights the payoff for all this work: as part of the commissioning activity in early February, we obtained a series of burns at two different locations in the G3 hutch while adjusting the angle of the toroidal monochromatic mirror. The middle burn in the lower left image shows the condition where the beam is focused at the sample position. Burns above and below this one correspond to mirror motions of 0.2 milliradians, and move the focal spot from downstream (top) to upstream (bottom) of this position. Slit scans at the sample showed the focused beam to be roughly 0.6 × 0.6 mm2, and the flux, measured using a diamond flux monitor, was in excess of 1.4×1014 photons/second.

Figure 5: (top) Layout of g-line indicating the location of the toroidal mirror and of the locations in G3 hutch where the beam shapes were captured by burn paper (lower left and middle) for different angles of the toroidal mirror (lower right).

As mentioned above, the effort from December-January required hard, conscientious work from just about the entire CHESS technical staff. As the G-line staff scientist, I’d specifically like to mention: Chris Conolly and Aaron Lyndaker for many efforts on many fronts — everything from project consultation and coordination to hands-on-equipment help at critical moments; vacuum expertise and elbow grease from Bob Seeley, Chris Whiting, Katie Moring and Kurt MacDonald; expert machining by John Kopsa and Jerry Houghton; smart brute force by Dana Richter and the riggers Jeff Mangus, Mitch Bush, Ed Foster and others; Peter Revesz and Zach Brown for the new horizontal beam position monitors; and survey work by CLASSE staff members Dragana Jusic and Hans Bruno. Moreover, this upgrade was the culmination of design work extending over the previous year primarily by Alan and Tom, but including conceptual design and purchases by mechanical engineer Karl Smolenski extending back to late 2013. It’s worth mentioning that the purchases themselves required a great deal of work and communication with vendors – and benefited enormously from our purchasing agents Todd Hawkins and Beth Wilcox. Congratulations to this exceptional team for a fantastic success!

Submitted by: Arthur Woll, CHESS, Cornell University

05/12/2016