X-RAY RUNS: Apply for Beamtime

2017 Nov 1 - Dec 21

2018 Feb 7 - Apr 3

2018 Proposal/BTR deadline: 12/1/17

2018 Apr 11 - Jun 4

2018 Proposal/BTR deadline: 2/1/18

CHESS is a leader in designing and fabricating single-bounce x-ray capillary optics technology for over 20 years. CHESS capillaries are designed to have rotationally symmetric ellipsoidal shapes to intercept a large beam area, and thus are suitable focusing optics for current CHESS beamlines which delivers an x-ray beam into 10~50um spot sizes with large x-ray flux.

As for CHESS-U and other 3rd Synchrotrons, both x-ray source size and emittance are getting smaller; a great leap in capillary technology is needed to meet growing performance requirements. Desirable capillaries should provide smaller focused beam size and/or extended x-ray energy regime as summarized in Table 1. To realize these properties, two new design approaches have been recently explored: Micron-scale Controlled Capillary (MC2-cap1) and Metal Coated Capillary (MC2-cap2). Several realizations of these new designs are summarized in Table 1.

Table 1: List of Several Capillaries on Demands. Capillary #1 to #3 are for micro focusing as a primary or secondary optics. Capillary #4 is a condenser for Transmission X-ray MICROSCOPE (TXM).

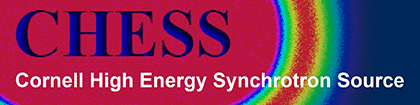

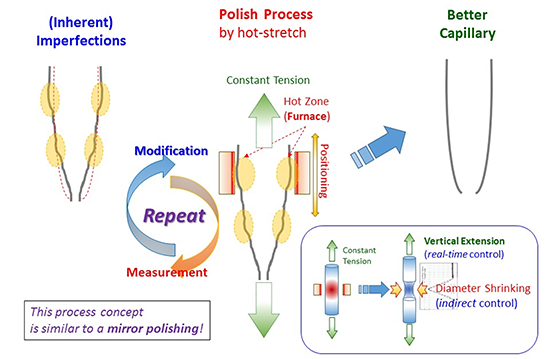

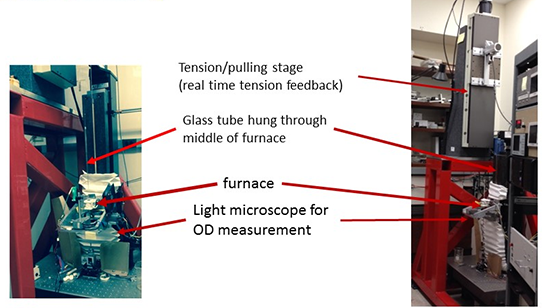

The goal of the MC2-cap1 effort is to realize a capillary with high profile accuracy and overall straightness at the micron scale. While achieving a perfectly shaped capillary in a single pulling process might be possible, our experience shows some limits (it either requires more luck of a master craftsman’s hand). On the other hand, to realize micron-scale perfection in MC2-cap1 in general, multiple (serially repeated) modifications and measurements (Figure 1) could be introduced to meet parametric tolerances. This is a kind of engineer’s work! The CHESS capillary puller shown in Figure 2 uses a stretch method inside a narrow hot zone (< 2 inches) to make a capillary under constant/variable tension. This hot-stretch is an irreversible process, i.e., it always causes tube diameter shrinking, thus iterative hot-stretch is similar to common mirror polishing processes that use rigorous measurements in sub-micron scale. Figure 3 depicts capillary profile accuracy as a function of number of corrections for Capillary #1 in table 1. Within a few iterations, shape accuracy reaches the submicron scale (that is divided by the ratio of tube outer-diameter/inner-diameter) over 10 cm length, which is longer than (exceeding) the designed capillary specification.

Figure 1: Process concept of micron-scale modification by iterative thermal process.

Figure 1: Process concept of micron-scale modification by iterative thermal process.

Figure 2: CHESS capillary puller Machine and its component.

Figure 2: CHESS capillary puller Machine and its component.

Figure 3: (a, left) A tendency graph of profile accuracy as function of number of corrections. (b, right) A capillary profile deviation from ideal profile. A profile accuracy in 2 um over 10 Cm length (dotted box) was achieved after 6 time corrections. This profiles is outer-DIAMETER (OD) profile, the actual capillary of inner-DIAMETER (ID) profile should be divided by OD/ID ratio.

Figure 3: (a, left) A tendency graph of profile accuracy as function of number of corrections. (b, right) A capillary profile deviation from ideal profile. A profile accuracy in 2 um over 10 Cm length (dotted box) was achieved after 6 time corrections. This profiles is outer-DIAMETER (OD) profile, the actual capillary of inner-DIAMETER (ID) profile should be divided by OD/ID ratio.

The realization of a high efficient condenser capillary (Cap #4) for use in a Transmission X-ray Microscope (TXM) is more challenging because of its large length, longer than 200 mm. TXM condenser capillaries are not for fine focusing but instead for defining a reasonable spot size and a large field of view, more than 30μm×30μm. Recently, sub-micron profile accuracy (peak-to-peak value, inner diameter) was demonstrated for a TXM condenser capillary having 300mm length. This work was also done using the iterative hot-stretch method. Iterative hot-stretch is a reliable way to realize good capillaries, given time and patience.

The aims of a metal coated capillary, MC2-cap2, are to extend the available x-ray energy regime higher than 30keV and to enhance gain efficiency by increasing intercepted beam area. For these purposes, increasing critical energy of x-ray reflectivity by proper thin layer metal coating is essential. High-Z metals or those compounds are desirable and both platinum and palladium are good candidates. CHESS will continue this develop by collaboration work with Cornell Nanoscale Facility (CNF) and German University in Lubeck.

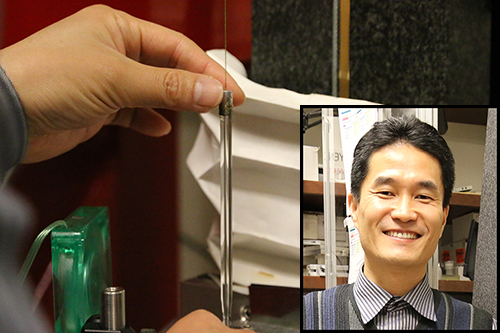

Over the course of the past year, continued improvement in CHESS capillary technology was aided by a series of minor technical upgrades to the puller machine to provide more stable and reproducible process condition. One important upgrade was installing a box enclosure around the whole pulling machine to prevent additional air flows into the process area. In all, fundamental upgrades and new methods approaches, as well as continuous technical upgrades, are all required to realize better x-ray focusing capillaries. CHESS is very grateful for the all the innovations and efforts in this area by Dr. Hyun Hwi Lee, a visiting scientist from the Pohang Accelerator Laboratory (PAL, POSTECH, Korea) (Figure 4). Over the course of a one-year visit he asked then answered his own question: “Can we make more reliable capillary optics?” “Sure, we found one way. but that’s not a shortcut. Now we need a master craftsman engineer.”

Figure 4: Dr. Hyun Hwi Lee with the CHESS capillary pulling tower.

Figure 4: Dr. Hyun Hwi Lee with the CHESS capillary pulling tower.

Submitted by: Hyun Hwi Lee and Rong Huang, CHESS, Cornell University

02/22/2017